If you’ve ever cracked open an AR-15, you know gunandpartspros.com is the beating heart of this modular masterpiece. It’s the workhorse that makes your rifle cycle, and picking the right one can mean the difference between a smooth-shooting range toy and a finicky jam-o-matic. Today, we’re diving deep into the world of BCGs—how they work, the finishes you can get, which ones reign supreme, and how to pick the best one for your build. Buckle up, because we’re about to get nerdy with it.

What Does a Bolt Carrier Group Do?

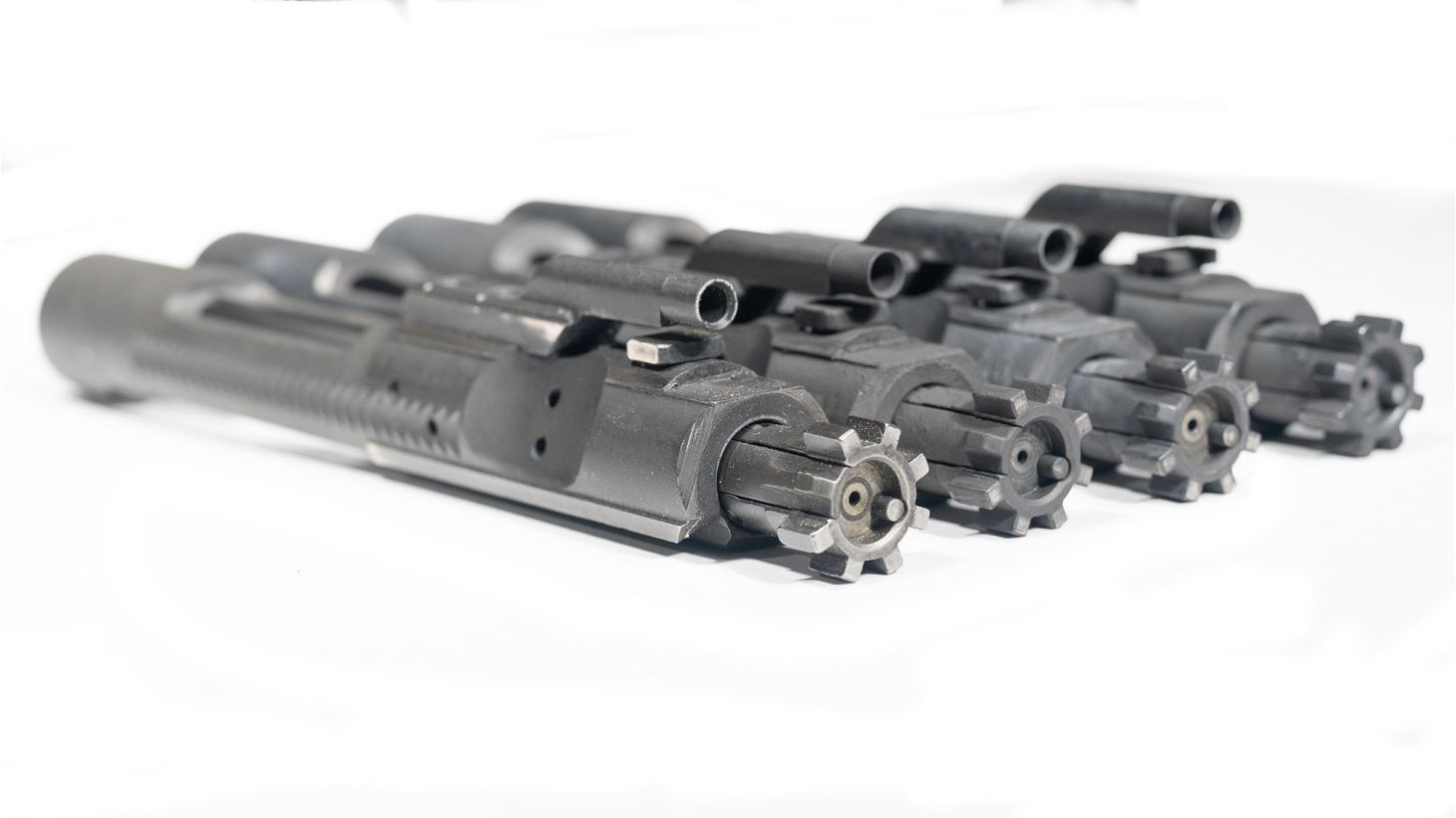

The BCG is the unsung hero of your AR-15, handling the critical tasks that keep your rifle running like a well-oiled machine. At its core, the BCG is responsible for chambering rounds, firing them, extracting spent casings, and resetting the action for the next shot. It’s a complex little beast, made up of several key components: the bolt, carrier, gas key, cam pin, firing pin, and retaining pin, all working in harmony.

Here’s how it goes down: when you pull the trigger, the firing pin strikes the primer, igniting the powder and sending the bullet downrange. The gas from that explosion travels through the gas tube, hits the gas key on the BCG, and pushes the carrier rearward. As it moves, the bolt unlocks, extracts the empty casing, and ejects it. The buffer spring then shoves the BCG forward, picking up a fresh round from the magazine and chambering it. Rinse and repeat. This cycle happens in a fraction of a second, and a good BCG makes it feel seamless.

A quality BCG is built to tight tolerances, ensuring reliable cycling under harsh conditions—whether you’re dumping mags at the range or running drills in the mud. Cheap BCGs, on the other hand, can lead to failures to feed, extract, or eject, turning your AR into a glorified paperweight. The materials, machining, and finish all play a role in how well it performs, which brings us to our next point

What Finishes Are Available for Bolt Carrier Groups and What Are Their Purposes?

The finish on a BCG isn’t just about looking pretty (though a slick-looking BCG does have range cred). It’s about durability, corrosion resistance, and ease of maintenance. Here’s a rundown of the most common finishes and why they matter:

- Phosphate (Parkerized)

The OG of BCG finishes, phosphate is the mil-spec standard. It’s a manganese or zinc phosphate coating that gives the BCG that classic matte gray look. Phosphate is tough, affordable, and holds oil well, which helps reduce friction and makes cleaning easier. It’s not the most corrosion-resistant option, but it’s battle-proven and reliable. If you’re building a no-frills, hard-use rifle, a phosphate BCG is tough to beat. Downside? It’s not as slick as modern coatings, so carbon buildup can be a pain to scrub off after a long day at the range. - Nitride (Melonite/QPQ)

Nitride, often called Melonite or Quench-Polish-Quench (QPQ), is a heat-treatment process that hardens the steel’s surface and adds a slick, black finish. It’s incredibly durable, corrosion-resistant, and smoother than phosphate, meaning less friction and easier cleanup. Nitride BCGs are a favorite for high-round-count shooters because they hold up under heat and abuse. They’re also budget-friendly compared to some high-end coatings. The only knock? They don’t have the exotic appeal of fancier finishes, but they get the job done. - Nickel Boron

Nickel boron (NiB) is the shiny, silver-coated rockstar of BCG finishes. It’s slicker than a used car salesman, reducing friction to a minimum and making carbon buildup wipe off like a dream. NiB is also highly corrosion-resistant, which is great for humid environments or if you’re running suppressed (where things get extra dirty). The downside? It’s pricier than phosphate or nitride, and the shiny finish can wear off over time, especially on high-contact areas like the carrier rails. Still, for a low-maintenance BCG that looks badass, NiB is a solid pick. - Diamond-Like Carbon (DLC)

DLC is the premium choice for BCGs, offering a super-hard, low-friction coating that’s tougher than a two-dollar steak. It’s jet-black, corrosion-resistant, and so slick it makes other finishes look like sandpaper. DLC BCGs are built for extreme durability and minimal maintenance, ideal for suppressed rifles or high-volume shooting. The catch? They’re expensive—sometimes double the cost of a nitride BCG. If you’re a baller on a budget, you might wince at the price, but for top-tier performance, DLC is hard to beat. - Chrome

Chrome-plated BCGs are less common today but were popular in early ARs. Chrome is insanely durable and corrosion-resistant, with a mirror-like finish that reduces friction. It’s still used in some high-end applications, especially for machine guns or rifles in brutal environments. However, chrome can be tricky to apply evenly, and quality control issues can lead to flaking. It’s also pricey and has largely been replaced by nitride and DLC for most shooters.

Each finish has its trade-offs, but your choice depends on your budget, environment, and how much you hate cleaning carbon off your BCG. Now, let’s talk about which BCG types stand out as the best.

What Is the Best Type of Bolt Carrier Group?

There’s no one-size-fits-all “best” BCG; it depends on your rifle’s purpose, budget, and preferences. That said, we can break down the main types of BCGs and highlight what makes them shine.

- Mil-Spec BCGs

Mil-spec BCGs, typically phosphate-coated, are built to military standards (think M16 or M4). They’re made from 8620 steel for the carrier and Carpenter 158 steel for the bolt, with proper staking on the gas key and rigorous testing (like high-pressure testing or magnetic particle inspection). These are reliable, affordable, and perfect for a general-purpose AR. Brands like Colt, BCM, and PSA’s Premium line deliver mil-spec BCGs that won’t disappoint you. Best for: budget builds, duty rifles, or anyone who wants proven reliability. - Lightweight BCGs

Lightweight BCGs, often made from aluminum or titanium with low-mass carriers, are designed to reduce recoil and speed up cycling. They’re popular in competition rifles where every ounce matters, like 3-gun or USPSA. Brands like JP Enterprises and V Seven make stellar lightweight BCGs, often with DLC or NiB coatings for extra slickness. The trade-off? They’re pricey, and the reduced mass can cause reliability issues with weaker ammo or dirty conditions. Best for: competition shooters chasing speed. - Adjustable BCGs

Adjustable BCGs, like those from Bootleg Inc., let you tweak the gas flow to fine-tune your rifle’s cycling. This is a godsend for suppressed rifles or overgassed setups, where too much gas can batter the BCG and cause premature wear. They’re typically nitride or DLC-coated for durability. The downside is the added complexity and cost, but for a custom-tuned AR, they’re worth it. Best for: suppressed builds or precision shooters. - Exotic Material BCGs

Some BCGs use materials like titanium or Inconel for the bolt or carrier to reduce weight or increase durability. These are often paired with high-end coatings like DLC. They’re exceptionally expensive but offer unmatched performance for specific applications, like ultra-light builds or extreme environments. Best for: operators with deep pockets or specialized needs.

So, what’s the best? For most shooters, a mil-spec BCG from a reputable brand like BCM or Toolcraft (nitride-coated for ease of maintenance) is the sweet spot—reliable, affordable, and versatile. A lightweight or adjustable BCG with a DLC or NiB finish might edge out the competition if you’re a competitor or running a suppressed rig. It’s all about matching the BCG to your mission.

How to Pick the Best Bolt Carrier Group

Choosing the right BCG is like picking the right tool for a job—it’s gotta fit your needs. Here’s a step-by-step guide to make sure you’re not throwing money at a BCG that’s wrong for your build:

- Define Your Purpose: Are you building a budget blaster, a duty rifle, or a competition rig? A mil-spec phosphate BCG is fine for a general-purpose AR, but a 3-gun shooter might want a lightweight NiB or DLC-coated BCG for faster cycling. Suppressed shooters should consider adjustable BCGs to manage gas blowback.

- Set a Budget: BCGs range from $80 for a basic Toolcraft phosphate model to $300+ for a DLC-coated, titanium lightweight BCG. Decide how much you’re willing to spend. A good nitride BCG from PSA or Aero Precision will run you $100-$150 and cover most needs without breaking the bank.

- Check Materials and Testing: Look for 8620 steel carriers, Carpenter 158 or 9310 steel bolts, and proper staking on the gas key. Reputable brands will list if their BCGs are high-pressure tested (HPT) or magnetic particle inspected (MPI). These tests ensure the BCG can handle the stress of thousands of rounds.

- Consider Your Environment: If you’re in a humid or coastal area, prioritize corrosion-resistant finishes like NiB or DLC. For dry, dusty conditions, a phosphate BCG’s ability to hold oil might be a better fit. Suppressed shooters should lean toward slick coatings to ease carbon buildup.

- Match Your Gas System: Ensure the BCG matches your barrel’s gas system (carbine, mid-length, rifle-length). Lightweight BCGs work best with properly gassed barrels to avoid short-stroking. Adjustable BCGs can compensate for overgassed setups.

Read Reviews and Stick to Reputable Brands: Brands like BCM, Toolcraft, Aero Precision, and JP Enterprises have a track record of quality. Check forums like AR15.com or Reddit’s r/guns for user feedback. Avoid no-name BCGs from sketchy retailers—they’re a gamble. - Pro tip: Don’t skimp on the BCG. It’s the heart of your rifle, and a cheap one can lead to malfunctions that ruin your day at the range or, worse, in a defensive scenario. Spend a little extra for peace of mind.

-

Wrapping It Up

The bolt carrier group is the soul of your AR-15, and choosing the right one is a balance of purpose, budget, and performance. Whether you’re rocking a mil-spec phosphate BCG for a bombproof duty rifle or a DLC-coated lightweight model for tearing up the 3-gun course, there’s a BCG out there for you. Understand what it does, pick a finish that matches your environment, and choose a type that fits your mission. Do that, and your AR will run like a champ. Now, get out there, build that rifle, and send some rounds downrange. Stay safe, and keep shooting straight.